How to Enhance Structural Fabrication Efficiency with Modern Techniques

Understanding Structural Fabrication

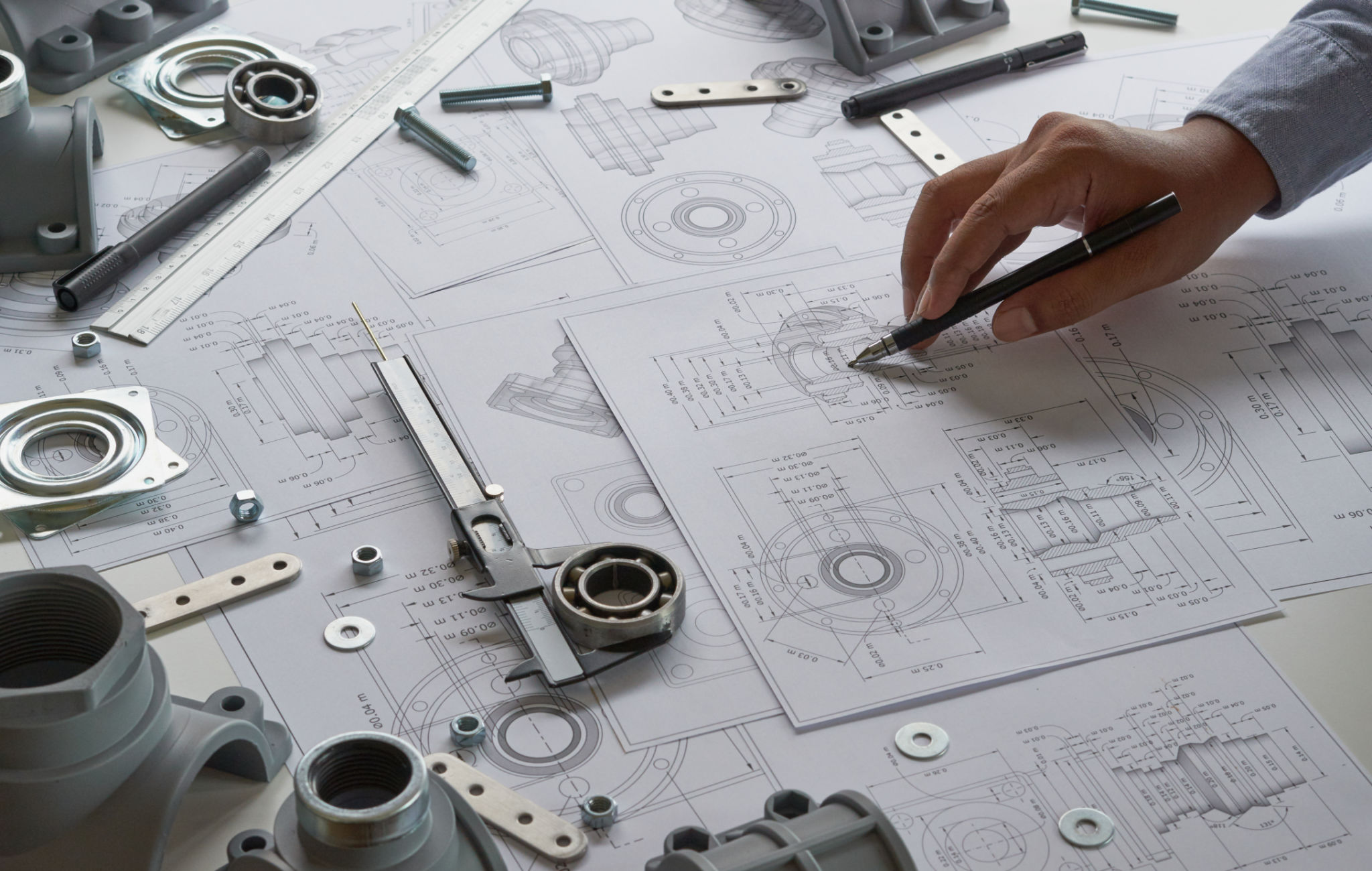

Structural fabrication is a crucial aspect of construction and engineering, involving the creation of steel frameworks for various structures. The efficiency of this process can significantly impact the overall success of a project, influencing timelines and costs. By adopting modern techniques, businesses can streamline operations, reduce waste, and enhance productivity.

Leveraging Advanced Technologies

One of the most significant advancements in structural fabrication is the integration of advanced technologies. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software have revolutionized how designs are created and executed. These tools allow for precise measurements and simulations, ensuring that the final product meets exact specifications.

Additionally, the use of 3D modeling provides a comprehensive visualization of the project before fabrication begins. This reduces the likelihood of errors and allows for adjustments in the planning stages rather than during construction, saving both time and resources.

The Role of Automation

Automation is another critical component in enhancing fabrication efficiency. Automated machinery, such as CNC machines, can perform complex tasks with high precision and speed. This reduces the need for manual intervention and minimizes human error. Furthermore, automation helps in maintaining consistency across products, ensuring that each piece meets quality standards.

Implementing Lean Manufacturing Principles

Lean manufacturing principles focus on maximizing value by minimizing waste. In structural fabrication, this can be achieved by optimizing workflows and eliminating unnecessary steps in the production process. By streamlining operations, companies can reduce lead times and improve overall efficiency.

An essential aspect of lean manufacturing is continuous improvement. By regularly reviewing processes and identifying areas for enhancement, businesses can sustain efficiency gains over time. This proactive approach fosters a culture of innovation and adaptability within the organization.

Enhancing Workforce Skills

Investing in employee training is vital for boosting efficiency in structural fabrication. Skilled workers are better equipped to handle advanced technologies and complex machinery, leading to improved performance and productivity. Regular training sessions ensure that employees stay updated on the latest industry trends and techniques.

Utilizing High-Quality Materials

The choice of materials plays a significant role in the efficiency of structural fabrication. Utilizing high-quality raw materials reduces the risk of defects and rework, which can be costly and time-consuming. By selecting materials that offer durability and reliability, businesses can enhance the longevity and performance of their structures.

Conclusion: Embracing Modern Techniques

Enhancing structural fabrication efficiency requires a combination of advanced technologies, automation, lean principles, skilled workforce, and quality materials. By embracing these modern techniques, businesses can optimize their operations, reduce costs, and deliver projects on time. The integration of these strategies not only boosts productivity but also ensures that companies remain competitive in a rapidly evolving industry.