Top 5 Myths About Metal Fabrication Services Debunked

Understanding Metal Fabrication

Metal fabrication is a vital process in numerous industries, yet it remains shrouded in misconceptions. As a result, many businesses hesitate to invest in these services due to misunderstandings. In this blog post, we aim to debunk the top five myths surrounding metal fabrication services to help you make informed decisions.

Myth 1: Metal Fabrication is Only for Large-Scale Projects

A common myth is that metal fabrication services are only suitable for large-scale industrial projects. While it's true that metal fabrication plays a crucial role in constructing massive infrastructures, it is equally essential for smaller projects. From custom metal parts for home renovations to intricate components for electronics, metal fabrication offers versatile solutions for projects of all sizes.

Myth 2: Metal Fabrication is Too Expensive

Many believe that metal fabrication is prohibitively expensive. However, the cost-effectiveness of metal fabrication often outweighs the initial investment. By leveraging advanced technology and streamlined processes, fabricators can produce high-quality parts efficiently, reducing waste and cost. Businesses can also save money in the long run by investing in durable, custom-fabricated components tailored to their specific needs.

Myth 3: All Metals Are the Same

Another misconception is that all metals used in fabrication are identical. In reality, the choice of metal significantly impacts the project's outcome. Different metals possess unique properties, such as strength, weight, and corrosion resistance, making them suitable for specific applications. Understanding these differences allows fabricators to select the right material for each project, ensuring optimal performance and longevity.

Common Types of Metals Used

- Steel: Known for its strength and durability.

- Aluminum: Lightweight and resistant to corrosion.

- Copper: Excellent electrical and thermal conductivity.

- Stainless Steel: Corrosion-resistant and low maintenance.

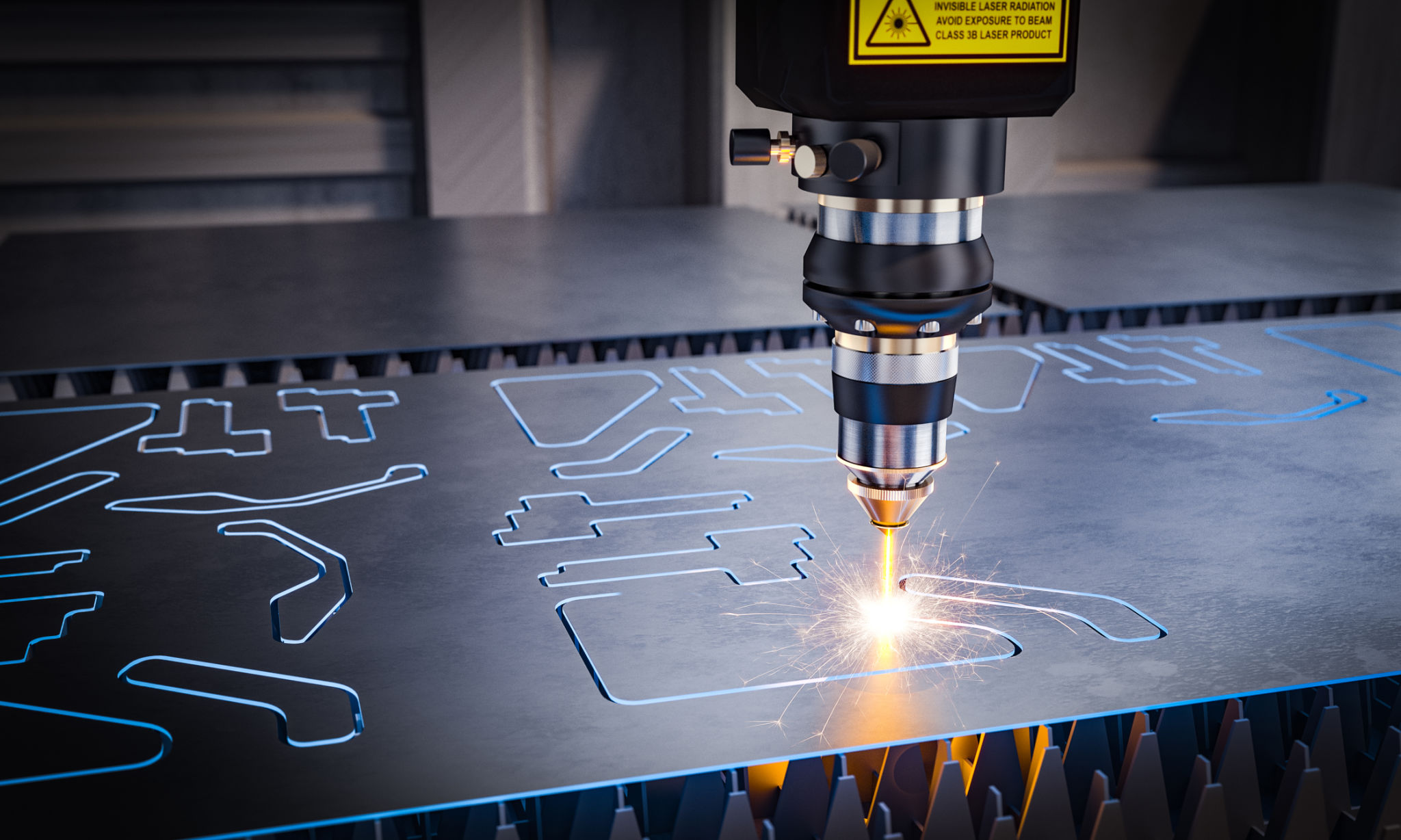

Myth 4: Metal Fabrication Lacks Precision

The misconception that metal fabrication lacks precision often deters businesses from utilizing these services. In fact, modern metal fabrication employs advanced techniques such as laser cutting, CNC machining, and robotic welding. These technologies ensure high precision and accuracy, allowing fabricators to produce intricate designs and complex geometries with ease.

Myth 5: Metal Fabrication is Environmentally Unfriendly

Some people assume that metal fabrication has a negative impact on the environment. However, many metal fabrication processes have become more sustainable over time. The industry increasingly focuses on recycling materials, reducing energy consumption, and minimizing waste. By adopting eco-friendly practices, metal fabrication companies strive to lower their environmental footprint while maintaining efficiency and quality.

The Role of Recycling in Metal Fabrication

Recycling plays a significant role in reducing the environmental impact of metal fabrication. By reusing metals like aluminum and steel, fabricators can conserve natural resources and reduce greenhouse gas emissions. Additionally, recycling often requires less energy than producing new materials from raw ores.

In conclusion, understanding the realities of metal fabrication services can open the door to a multitude of possibilities for businesses across various industries. By debunking these common myths, we hope to provide clarity and insight into the benefits and capabilities of modern metal fabrication.